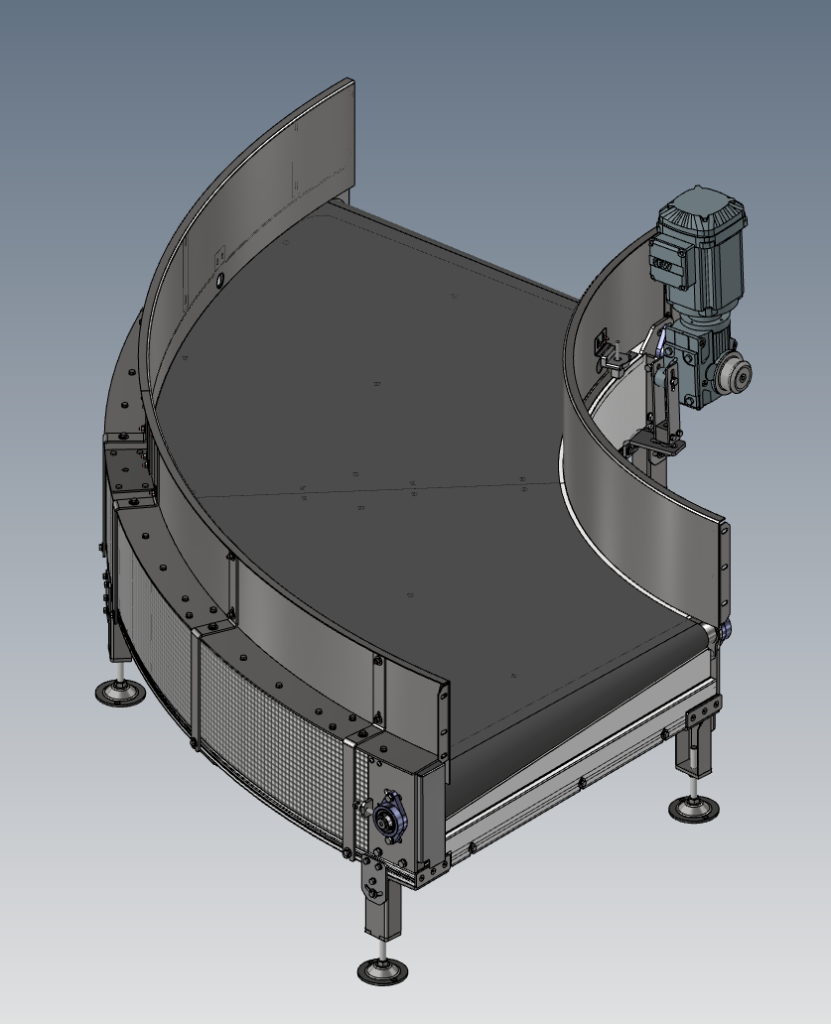

Rapid Release Powered Belt Flat Curve

Our game changing Rapid

Release Powered Belt Flat Curve

Conveyor ensures full

accessibility for ease of

maintenance and part exchange.

ensuring minimal disruption to

valuable operation time.

Subsequent to ourinitial R&D and extensive testing, we

have been confidently supplying the Kairos Curve across 4

continents, to major global integrators and international

brand end users since the beginning of 2017.

Rapid Release Powered Belt Flat Curve

Ourgame changing Rapid

Release Powered Belt Flat Curve

Conveyor ensures full

accessibility for ease of

maintenance and part exchange.

ensuring minimal disruption to

valuable operation time.

Subsequent to ourinitial R&D and extensive testing, we

have been confidently supplying the Kairos Curve across 4

continents, to major global integrators and international

brand end users since the beginning of 2017.

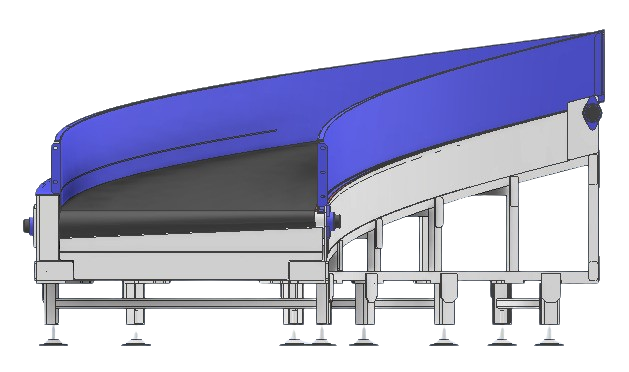

Rapid Release Powered Belt Spiral Curve

Our unique design, featuring vertical pillars as an integral part of the frame and our rapid release guidance system, to genuinely ensure a very short down time during belt, pulley and bearing replacement.

Twisted Sub-Frame for

Height Variability

twisted sub-frame positioned above the base

frame to achieve the required variable height

differences.

Slider Bed Frame Construction

twisted with a heavy-duty mild steel profile

rolling machine, and the slider bed material is

standard galvanized steel plate.

Aluminum Sub-frame

Rolling Process

attachment on our specialist CNC aluminum

profile rolling machine.

Slider Bed Frame Construction

Height differences can range from 100mm to

600mm per 90°, depending on the inner radius

gradient, with any angle between 45° and

180°.

Benefits of Kairos Curve Design

Rapid Belt Removal

and Easy

Maintenance

Game-changing belt guidance retaining

system ensures “rapid release” of the

beading from angled trap bearings, enabling

quick removal of the

vulcanized endless belt.

Entire operation is visible during use, allowing

for visual inspections of the

belt, beading, pulleys, and bearings

while running.

All housings and pillars can be easily

removed by releasing a maximum of 3

bolts.

Time-consuming removal of the

deck board is unnecessary during belt

replacement, as we have designed our curves with cantilevered supports, extending from the outer radius to the center.

Advanced Detection

and Safety Features

Photocell and reflector can be

positioned extremely close to the belt

surface to detect low-profile products.

Latched under guards come as standard

for easy removal.

Performance and

Noise Levels

Speeds of up to 120 m/min with loads up

to 60kg/m per meter, ideal for typical

airport and parcel operations.

Low noise levels below 68 dBA.

Efficient Bearing Replacement

Individual bearing replacement can be conducted with minimal

downtime, as each bearing holder seat is easily removed and replaced without tools.

For full bearing replacement, alternate holder pillar

“cassettes” can be removed and serviced remotely while the unit continues operation.

Flexibility and Accessibility

Any angle or belt width possible without additional engineering cost for “non-standard” sizes.

Flexible pulley diameters (100mm to 200mm) are available to accommodate various speed and load requirements.

Pillars are spaced to allow easy access from the outerradius to

the inner workings of the curve.